In our last blog post, we reviewed how the Firwin FireBlanket 2000 protects industrial safety valves and actuators.

We explained how a removable insulation blanket designed to protect safety valves is different from the standard insulation blankets you’ll find in industrial settings. In this blog post, we’ll talk more about the design of this type of fire blanket and explain how strong and durable it is (and why it needs to be this way!).

The Firwin FireBlanket 2000 is designed to keep the heat and fire away from the part. Typically, removable insulation blankets are composed of three layers:

1. the inner surface

2. the insulation material that rests on the inner surface

3. the outer protective cover.

In most cases, the removable insulation blanket’s inner surface is the “hot face” that comes in direct contact with the hot component. However, the Firwin FireBlanket 2000’s outer protective cover is the “hot face” and it needs to withstand extremely high temperatures. The FireBlanket is working “in reverse,” in layman’s terms: The outer surface and insulation are protecting the part from the heat, and the outer protective cover needs to withstand the very high heat of a fire.

There are also other variables that come into play in a fire safety situation at an industrial plant, and time is a critical factor. The valve or actuator being protected by the FireBlanket will need to function and operate properly to allow enough time for the operator to shut down a line. In situations like this, a FireBlanket’s outer cover may deteriorate too quickly if it’s not manufactured to meet certain fire standards. It’s also important to install the FireBlanket so that the component is properly protected – an improperly installed FireBlanket could impede the blanket’s ability to protect the component in case of fire.

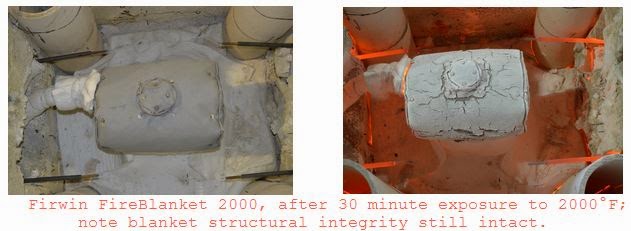

The Firwin FireBlanket 2000 easily passed the UL rapid rise fire standard test (UL1709) where it was placed in a special compartment and blasted with 2000-degrees-Fahrenheit temperatures for 30 minutes. The fire blanket – including its outer protective – remained fully intact throughout the test, with no signs of deterioration at all. This proves that the Firwin FireBlanket 2000 can definitely take the heat!

Removable insulation blankets are great at managing heat. Be it by lowering the ambient heat in an engine room, protecting workers from hot surfaces, or shielding pipe contents from cold external temperatures, removable insulation covers are often the solution of choice where heat must be managed, but permanent insulation is not feasible.

Removable insulation blankets are great at managing heat. Be it by lowering the ambient heat in an engine room, protecting workers from hot surfaces, or shielding pipe contents from cold external temperatures, removable insulation covers are often the solution of choice where heat must be managed, but permanent insulation is not feasible.